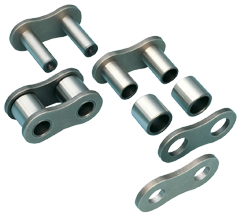

Chain lubrication requires a special lubricant

Lubrication of industrial chains requires a lubricant that complies a number of specific requirements that are not always easy to combine.

First, the lubricant should penetrate between roles, bus and pen. Maximum lubrication between them is of great importance: the lifespan depends strongly of the lubrication. But the grease should not be glide off: you otherwise keep lubricating and too much grease will drip on the machine or on the floor which creates waste and dirty conditions. Then, moisture and dirt/ dust should be repelled to reduce wear and maximize the lifespan of the chains and to prevent corrosion. Therefore, the lubricant should not be too sticky as otherwise dirt / dust will get attracted to they contaminate the chain. With as a result: the maximum lifespan will not be to achieved.

Not every chain is the same, and not every application or circumstance is the same. Below is a list of chain lubricants which can be used in an industrial environment.

More information?

If you cannot find what you are looking for or want more information, please fill out the contact form. We will handle your request promptly and professionally. You may also directly contact us by phone at 0031 78-651 23 22.

Chain Lubricants:

- Bardahl Foamy Lube Spray (high pressure lubricant)

Bardahl Foamy Lube Spray is scientifically formulated, long lasting, extreme pressure lubricant which operates under the most severe pressure and abrasive conditions. This product is developed as industrial Chain Lubricant but is also suitable for a numerous of other applications. It contains Bardahl’s famous “Polar attraction” formula to reduce friction.

After penetrating, Bardahl Foamy Lube clings, leaving a lasting coating that cuts friction, protects against corrosion and grime, and repels moisture.

Ensures that the surface to spray is cleaned firstly. Bardahl Multi Parts Cleaner is very arranged for cleaning this.

Properties

• Penetrates in accessible areas

• Repels and protects against water, moisture, salt, alkalis acids, dirt, dust, sand, etc.

• Developed for lubrication of parts subject to high pressure, shocks and vibrations.

• Protects moving parts and prevents squeaksSee the productvideo of our Foamy Lube Spray

Read more about Foamy Lube Spray Ref 72500

- Bardahl OGW Compound (protection/ conserving)

Bardahl Open Gear & Wire Compound is specially formulated for use on exposed gears, wire ropes and chain/sprocket drives. This product is designed to provide extra protection against wear, rust and corrosion, even under severe operating conditions.

The problem

Open gear mechanisms are typically subject to adverse conditions including high service loads, exposure to the elements, and contamination from dirt and other abrasive materials. Wire ropes and chains are often exposed to corrosive conditions, and are subjected to abrasion and temperature extremes. Rapid corrosion and wear under these severe conditions, can cause excessive down time and high replacement costs.The action

Bardahl Open Gear & Wire Compound is a penetrating lubricant for cables and wire ropes which provides a resilient coating that won’t be thrown off or washed out. On open gears, it provides a durable adhesive coating which protects against contamination, corrosion, and wear due to high pressure and heat. Bardahl OGW Compounds are ideal for protecting equipment such as turn buckles, shackles, cable clamps, exposed bolts, levers and switches against adverse environmental conditions.Applications

• Protection of cables, open cog wheels of taps, dragline excavators, excavators etc.

• Protection of agriculture – and ground resistance machines, as well as articulation points of cars such as pedals, car doors, brake systems etc.

• Protection and conserving of steel cables, as well as cable transits.

• Protection of open cog wheels, collars, cables, role-lower which itself under water and if in the immediacy of are substance, coal dust and mud

• Protection of rolling mill-lower against corrosion and of all surfaces, which work in an acid atmosphere such as open cog wheels in paper factories, cement factories etc.

• Protection of components of mud mills and lock doors which are continuously immersed in water (also water salts).

• Occur of rust of crap and wreck, if lubricated for assembly, like e.g. at car expresses frameworks, feather straps, bumpers – and other affirmatives which will not be demonstrated under not favourable circumstances for a long time. These applications are of course also applied in the industry and shipping.Main differences between OGW (72204) and OGW Transparent (72215)

OGW OGW Transparent

Colour Black Transparent

Smell yes nearly

Dries out yes no, stays wet and sticks to the parts

Protects yes, primair ja but primair is lubrication

Lubrication no yes, strong attaching, perfect co/ adhesiveRead more about OGW Compound Ref 72204

- Bardahl OGW Compound Transparant (lubricant)

Bardahl Transparent OGW Compound is specially formulated for use on exposed gears, wire ropes chain/sprocket drives and sliding jibs. This product is designed to provide extra protection against wear, rust and corrosion, even under severe operating conditions.

The problem

Open gear mechanisms and sliding jibs of cranes are typically subject to adverse conditions including high service loads, exposed to the elements, and contamination from dirt and other abrasive materials. Wire ropes and chains are often exposed to corrosive conditions, and are subjected to abrasion and temperature extremes –20°C up to 150°C. Rapid corrosion and wear under these severe conditions, can cause excessive down time and high replacement costs. Use where steam or hot and cold water is a problem. For situations where lubricant ‘spatter’ or dripping is not acceptable.The action

Bardahl Transparent OGW Compound is a penetrating lubricant for cables, wire houses and sliding jibs which provides a resilient coating that won’t be thrown off or washed out. On open gears, it provides a durable adhesive coating which protects against contamination, corrosion, and wear due to high pressure and heat. Bardahl Transparent OGW Compounds are ideal for protecting equipment such as turn buckles, shackles, cable clamps, exposed bolts, levers and switches against adverse environmental conditions.Application

• Construction equipment

• Trucks and Trailers

• Road maintenance equipment

• Marine and fishing equipment

• Repackaging industry

• Paper works

• Agriculture equipment

• Fair-attraction equipment etc.OGW OGW Transparent

Colour Black Transparent

Smell yes nearly

Dries out yes no, stays wet and sticks to the parts

Protects yes, primair ja but primair is lubrication

Lubrication no yes, strong attaching, perfect co/ adhesiveRead more about OGW Transparant Ref 72215

- Bardahl SHP Grease (water repellent grease)

Bardahl SHP Grease is a water resistant, high quality complex grease with mineral oils. This calcium based grease provides long lasting protection, lubrication and reduces wear.

Applications

Bardahl SHP Grease has been developed for the lubrication of a large variety of applications such as bearings, shafts, chains, gears, central locking systems, door mirror locks, sun roof mechanisms and springs.

It is suitable for extremes of temperature – high and low and is corrosion resistant. It will not attack rubber.Read more about SHP Grease Ref 74800

- Bardahl Special Purpose No Melt Grease (high temperature grease)

Bardahl Special Purpose No Melt Grease is designed for lubrication of machine parts for use between -20°C and 250°C and occasionally, to 340°C. It has also proved to be superior grease for centralized systems due to its low pressure bleed and good water wash out qualities. Conventional greases soften in extreme heat, such as that caused by high-speed equipment, high temperature environments, or prolonged service at above average temperatures. These conditions need a special high-heat resistant grease.

The problem

Chains, conveyors, and sleeve bearings in ovens are subjected to constant operating temperatures in excess of 200°C. At such sustained high temperatures ordinary soap based greases run off metal surfaces, allowing increased wear and friction. Separation of oil and thickener under pressure will give increased wear to lubricated parts and can cause expensive machinery repairs.The action

Bardahl Special Purpose No Melt Grease uses a non-soap clay thickener which forms an extremely stable grease that has no measurable dropping point. At temperatures where other greases run off metal surfaces, this product withstands high temperature environments of high speed equipment or prolonged service at above average temperatures.This grease has a typical working temperature-range of -20°C to over 250°C. It is immune to temperature changes at all ranges, highly adhesive to metal, water resistant and protects against wear and friction.

As a general rule grease with different thickening agents should not be mixed. Bardahl Special Purpose No Melt Grease should not be mixed with non-Bentone greases. Such mixing will lead to an immediate separation of oil and thickener. When first applying Special Purpose in centralized systems, make sure the equipment has been flushed of previous grease.Read more about Special Purpose No Melt Ref 74200

- Bardahl Super TF lube +PTFE (lubricant with teflon)

Bardahl Super TF Lube + PTFE is scientifically formulated for long lasting lubrication under the most severe pressure and abrasive conditions. The unique combination of synthetic lubricants and PTFE (polytetrafluorethylene) powder will form a very tough lubricating film on metal surfaces. Reduces and eliminates surface friction and wear. It penetrates in inaccessible areas, repels and protects against water, moisture, salt, alkalis, acids, dirt, dust, sand, etc. Specially developed for lubrication of parts subject to high pressure, shocks and vibrations. Protects any moving part and prevents squeaks. Working temperature from -50°C to +265°C. Color transparent.

Properties

• Provides long lasting lubrication

• Increases life

• Reduces friction

• Reduces wear of metal surfaces

• Protects against corrosion

• Penetrates

• Stops squeakingPTFE is the most slippery substance known. The PTFE-type used in this product is an excellent lubricant additive for specialized oils. It is special designed for conditions where conventional additives such as graphite and molybdenum disulphide are unsuitable.

Applications

Linkages, cables, hinges, chains, bearings, axles, locks, tracks, drives, zippers, etc. All kind of industrial equipment but also for Garden tools, bicycles, lawn mowers, camping gear, and on anything that slides, swivels, rolls or squeaks.Read more about Super TF Lube Ref 73504

- Bardahl TF Dry (dry lubricant with teflon)

Bardahl TF Dry is a concentrated synthetic lubricant scientifically compounded for dry lubrication and extreme pressure, based on Teflon basis. It reduces friction and prevents sticking. It is an unique all-purpose lubricant for numerous applications. After application it dries instantly leaving a dry, non-oily, clean, PTFE-powder surface, the slipperiest substance known to science. This product will function under a wide variety of conditions, ranging from cryogenic temperatures to 260°C or higher.

The problem

Assembly of equipment with close tolerances requires lubricant, which will not be scraped off during break in. Normal oils and greases, even ones containing graphite of molybdenum-disulfide, do not adequately meet this specialized requirement.

Chains and conveyors need a lubricant with high penetrating and corrosion resistant properties, as well as one which contains a minimum level of oil or slow evaporating solvent in order to prevent “fling off” and attraction of grime to lubricated parts.

Certain industrial applications require not only good lubrication but also the ability of the lubricant to remove existing grime to maintain or improve performance.The working

Bardahl TF Dry will form an effective lubricating surface on any material – wood, metal, leather, plastic, elastomers, fibers, glass, etc. A thin coating can easily be applied by the aerosol package. The lubricating protecting film is very thin, very adhesive, non-oily and will penetrate in the smallest places. It has an extremely low friction coefficient and will therefore reduce “stick-slip” problems to a minimum.

Characteristics

• Is a non-oily clean dry lubricant.

• Dries very fast and leaves no oil film or wax.

• It will not collect dirt or dust.

• Resists corrosion by acids or alkali’s.

• Will not be affected by water, oil or solvents.

• Prevents materials sticking in molds, bins, tanks, etc.

• Will not melt or freeze.Applications

• Sliding mechanisms, nuts, bolts, cables, tools, conveyors – anywhere a dry powder lubricant is required up to 260°C.

• For lubricating pump-shafts and valve stems just prior to installing packing, and in the installation of flange gaskets for easier disassembly.

• As breaking-in lubricant for packings (prevents sticking). A light coating on the wearing surfaces of the packing and shaft will provide extra protection during critical start-up period of newly installed packing.

• For conveyers, slides, mechanisms requiring a non-staining lubricant.

• For drawer sliding surfaces and windows.Read more about TF Dry Ref 72900